We Deal In-

Fire-clay refractory bricks are essentially hydrated aluminum silicates with minor proportions of other minerals. As a type these refractory bricks are extremely versatile and therefore can be put to numerous uses. These bricks are usually least costly of all refractory bricks and are extensively used in various industries including iron and steel industry, nonferrous metallurgy, glass industry, and cement industry.

High Alumina Bricks are a kind of commonly used refractory materials for sale in our Company, which is mainly made of Al2O3. High Alumina Brick has properties of high refractoriness, high strength, acid and washing erosion resistance, good thermal stability and so on. High Alumina Bricks are widely used in industries of blast furnace, hot blast stove, electric furnace, refining furnace and glass furnace and so on furnaces, tunnel kilns, Boiler plants between water tubes, door casting, ash hoppers, lime kilns, annealing furnaces etc

This is general purpose castable Refractory which can meet temperature up to 1200 deg cent. It can be used for dense casting also where shapes of over 4-inch thickness need to be casted. It can be used in steel works, billet furnaces, tunnel kilns, Boiler plants between water tubes, door casting, ash hoppers, lime kilns, annealing furnaces etc. We manufacture following Dense High Heat castables

Acid resistant bricks are made of raw materials, such as clay of suitable composition with low lime and iron content vitrified at high temperatures in ceramic kilns.

We manufacture & provide the best quality Low cement castables at reasonable prices.

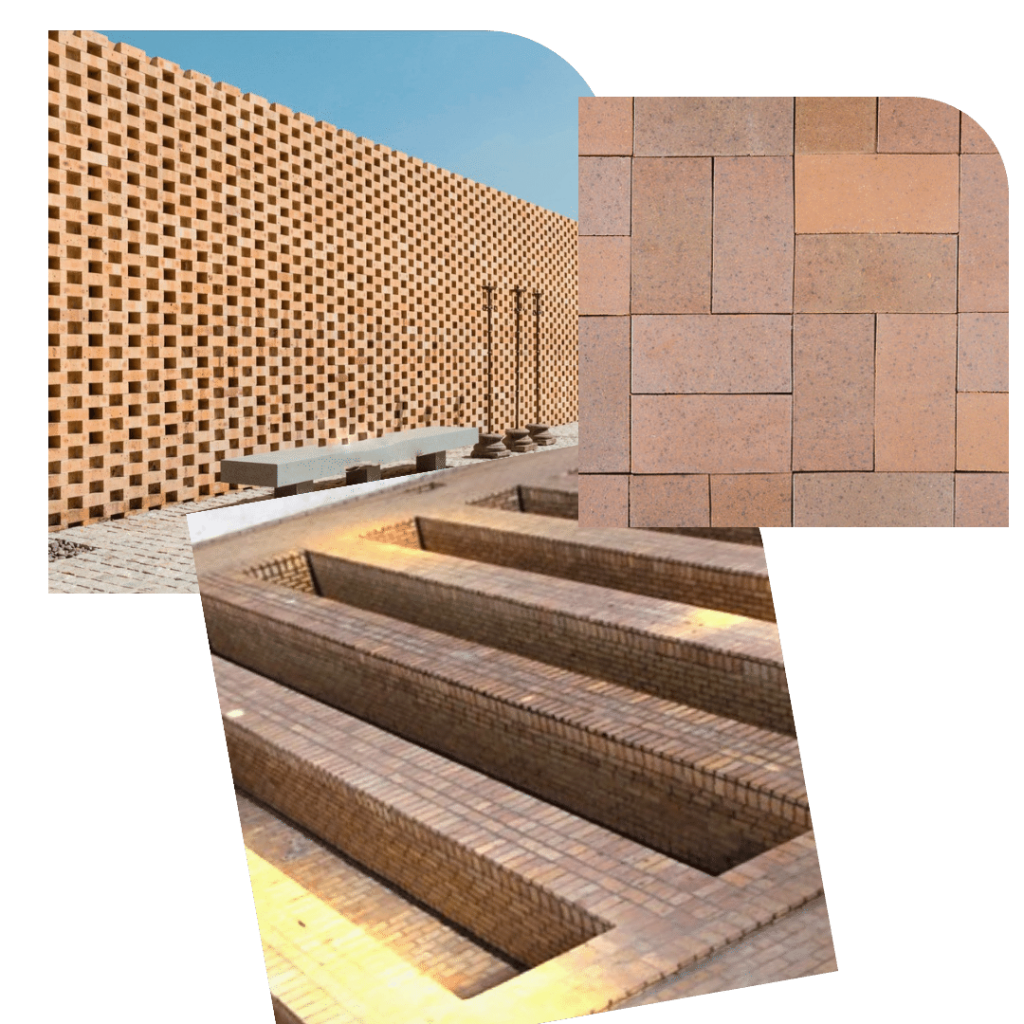

Bricks of special shapes and sizes are necessary to provide for changes in surface alignment, to top a wall or just for decoration

According to customer demand, given shapes drawing or description, we are manufacturing all sizes and shapes of refractory bricks with working temperature of 800 °C- 1800 °C.

To arrest the thermal radiation loss and to check the heat losses of furnace for longer life of linings, different qualities of Insulating Refractories (Both cold & hot face) are supplied according to the application areas. Insulation Bricks find application in Iron & Steel, Cement, Chemical, Copper, Glass plant &other miscellaneous Industries. These bricks have densities and conductivities ranging from low to moderate, low thermal expansion and very high resistance to thermal spalling.

White heat K (Castable White Heat K) is a designed ready mixed castable made from a high purity Calcium Aluminate binder and selected hard burnt dense refractory materials.